Printed tapes: Fabo’s flagship

The customisation of adhesive tapes is one of the most requested services by Fabo customers.

Customised tapes account for 20% of the volume sold in a year, a percentage that will grow over the years. Indeed, the figures speak of an increase of +13% in 2022 over the previous year.

Fabo’s technology provides high definition print quality, with the ability to brand the tape by printing logos, messages and various graphics to communicate your brand in an effective and original way.

The tapes can be customised on various backings: biaxially- and monoaxially-oriented polypropylene (BOPP, reinforced BOPP, MOPP), polyethylene (PE), polyester (PET – polyethylene terephthalate) and paper, with either acrylic or hot melt adhesive.

Types of flexographic printing: back and sandwich

Fabo can print on adhesive tape using two types of flexographic printing methods: back and sandwich.

These are two types of printing that differ in quality, strength of the printed image and cost of production.

What is the difference between the 2 types of printing?

Back flexographic printing

Back printing is a three-colour flexographic printing method. The work cycle starts with a 150 mm strip reel that is unwound, printed with a thermoregulated Teflon-coated counter-printing cylinder, cut lengthwise and rewound on two rewinding turrets. This is a print made precisely on the back of the tape (hence the name), i.e. on the outside of the media. It can be applied by corona treatment, in the case of water-based acrylic technology, or by the use of a printable release in the case of hot melt adhesive tapes.

What are the advantages of flexographic back printing?

The advantages of back printing are, primarily, time and cost. Machine processing times are faster and print costs are reduced compared to sandwich printing. These two aspects make it possible to speed up the production of more customised adhesive tapes.

However, the print can lose quality over time: because it is applied directly on the back, the ink used loses its sharpness, brilliance and graphic performance.

Sandwich flexographic printing

Flexographic sandwich printing, on the other hand, is a direct rotary printing method that uses embossed plates of rubber or photopolymer materials, known as clichés (printing plates). The plate is a matrix used to transfer the image onto the medium to be personalised. The stencil is relief-printed, flexible and soft, and is wound on a cylinder. Printing is direct: the plate transfers ink directly to the backing to be printed by means of a light pressure applied by a pressure cylinder. It is commonly called ‘sandwich’ because the ink is inserted on the inside, between the film and the adhesive.

What are the advantages of sandwich flexographic printing?

The resulting prints are qualitatively superior, sharper, brighter and more durable. The ink protected between the two layers thus resists abrasion from use and ageing of the tape, ensuring a longer life span. Another advantage is the possibility of four-colour printing.

On the other hand, however, the machine preparation steps are longer and consequently entail higher processing costs. As a result, sandwich printing is usually used for customisation of large quantities of adhesive tapes, so as to spread the cost of preparation over the total number of rolls.

5 reasons to choose a printed tape:

- Tape is the ideal medium for packing and sealing boxes of all kinds and sizes, quickly and economically;

- The tape offers unquestionable protection for the goods to be packed or shipped and protects them from tampering and signs of break-in;

- The printed tape is a marketing tool: by printing the logo or other message, the package is recognisable at first glance by the recipient or anyone who comes into contact with it;

- Printed tape is a tool for simplification: by customising the packaging, the storage and dispatch procedures themselves are smoother, faster and more efficient;

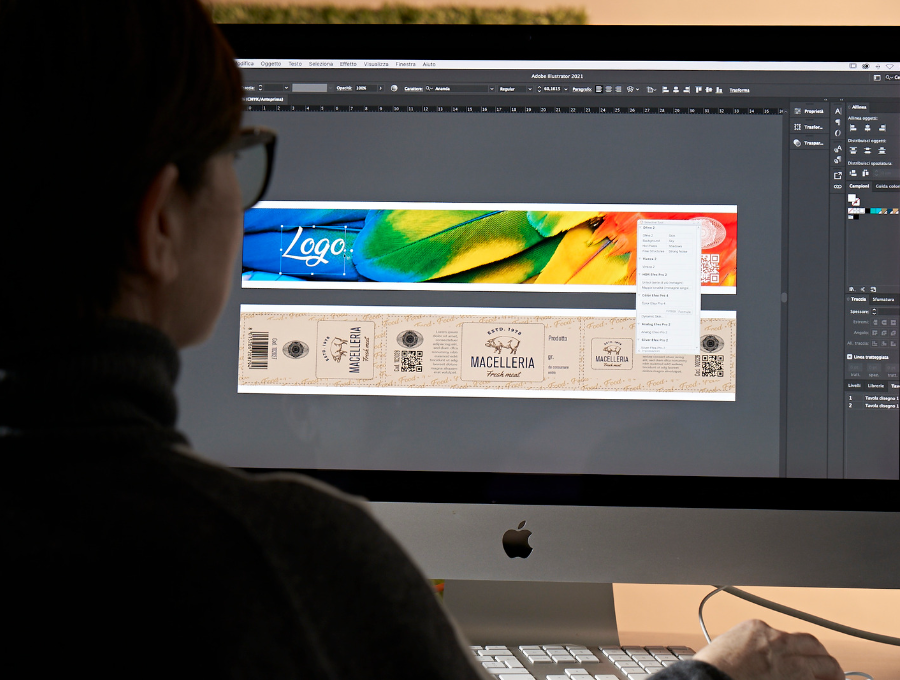

- Fabo’s graphics department is able to provide assistance to the customer, supporting him in the development of the printing project, following the technical production of the graphic applications to be applied on adhesive tapes, and also producing other customisations on sleeves, labels and boxes on request.