Adhesive tape is a seemingly simple product, but its effectiveness depends on a combination of factors, including the adhesive quality and, above all, the type of substrate used.

The substrate, i.e. the material to which the adhesive is applied, determines the characteristics of the tape itself, by influencing its adhesiveness, resistance, flexibility and many other properties.

Plastics: polypropylene, polyethylene and polyester

Plastic substrates are among the most common in the adhesive tape industry for their versatility and excellent performance.

Among these, polypropylene (both in mono-oriented – MOPP – and biaxially-oriented – BOPP – versions) is particularly appreciated for its mechanical strength and flexibility. The polypropylene substrate, whether mono- or biaxially-oriented, can be further treated to improve or modify its performance for instance through impregnation with resins or other treatments that affect the material’s properties by increasing its resistance and tensile strength.

Polyethylene (PE) is known for its flexibility and mechanical strength and is ideal for applications requiring high surface adaptability. As a matter of fact, PE-made adhesive tapes do not break or deform even under stress, adapting and stretching to and with the application surface.

Polyester (polyethylene terephthalate – PET), on the other hand, offers excellent chemical, mechanical and thermal resistance, making it perfect for heavy-duty industrial applications. It is particularly suitable for adhesive tapes intended for packaging and strapping as it offers outstanding dimensional stability, high breaking load and high adhesion to the end product.

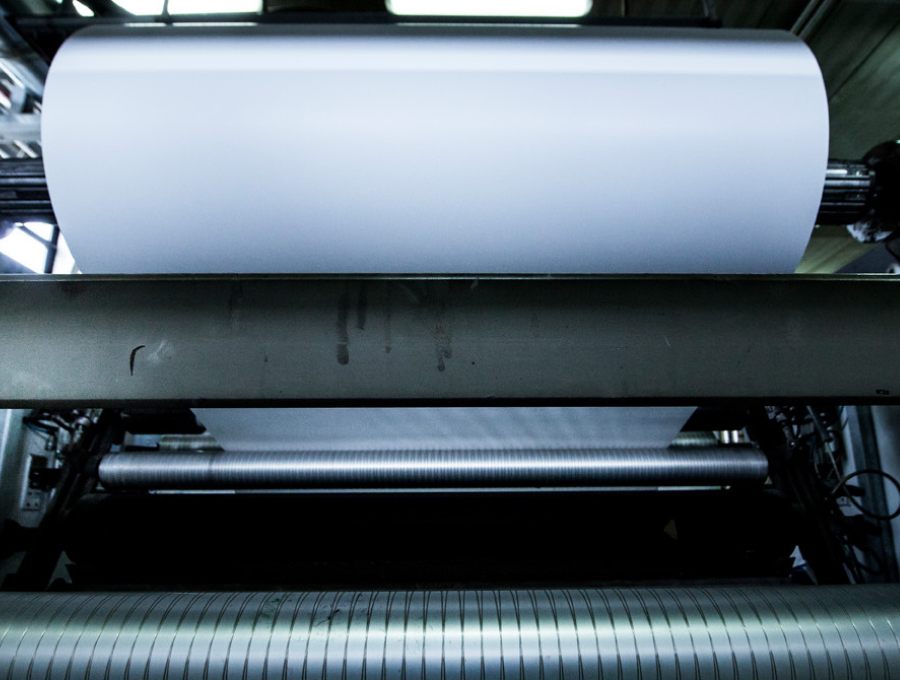

Paper substrate: natural and performing

Paper, whether saturated or impregnated or kraft, is an environmentally friendly and high-performance alternative to plastic substrates.

Saturated or impregnated paper is treated with resins or synthetic rubbers to improve its mechanical properties and make it suitable for adhesive coating. More commonly known as self-adhesive paper, it is processed by FABO with Hot Melt adhesive and can come in both smooth and reinforced versions.

Kraft paper, made from cellulose fibres, is known for its strength and resistance, as well as its ability to absorb moisture, thanks to its high breaking load and versatility in a variety of applications. It is a 100% ecological support, composed of natural substances and, consequently, totally disposable in paper. This type of substrate is associated with an adhesive of natural origin that activates when wet with water.

Both paper substrates can also be reinforced with textured and unidirectional processing, which give greater strength to the end product, thus making it ideal for both packaging and reinforcement solutions.

Non-woven fabrics: versatile and durable

Non-woven fabrics (Tessuto Non Tessuto – TNT) are made from woven or needle-punched fibres, without the use of spinning. This characteristic gives adhesive tapes with TNT substrate a high strength and tear resistance, making them more conformable to application surfaces and promoting good adhesion to many types of surfaces.

Choosing the right substrate

The substrate choice depends on several factors, including:

- Application: packaging, masking, fixing, sealing, palletising, protection, reinforcement;

- Environmental conditions: temperature, humidity, presence of chemicals;

- Characteristics of the application surface: smooth, rough, porous;

- Required performance: adhesiveness, resistance, flexibility.

FABO offers a wide range of adhesive tapes made with different types of substrates to meet every need. Thanks to our experience and customisation capabilities, we can advise you on the most suitable solution for your application, while guaranteeing maximum efficiency and quality in terms of adhesion, seal and use.

All substrates used for manufacturing FABO adhesive tapes can also be customised with flexographic printing. In fact, 30% of the adhesive tapes produced annually at FABO are tailor-made.

Contact us for more information on customising FABO products, click here: contact us